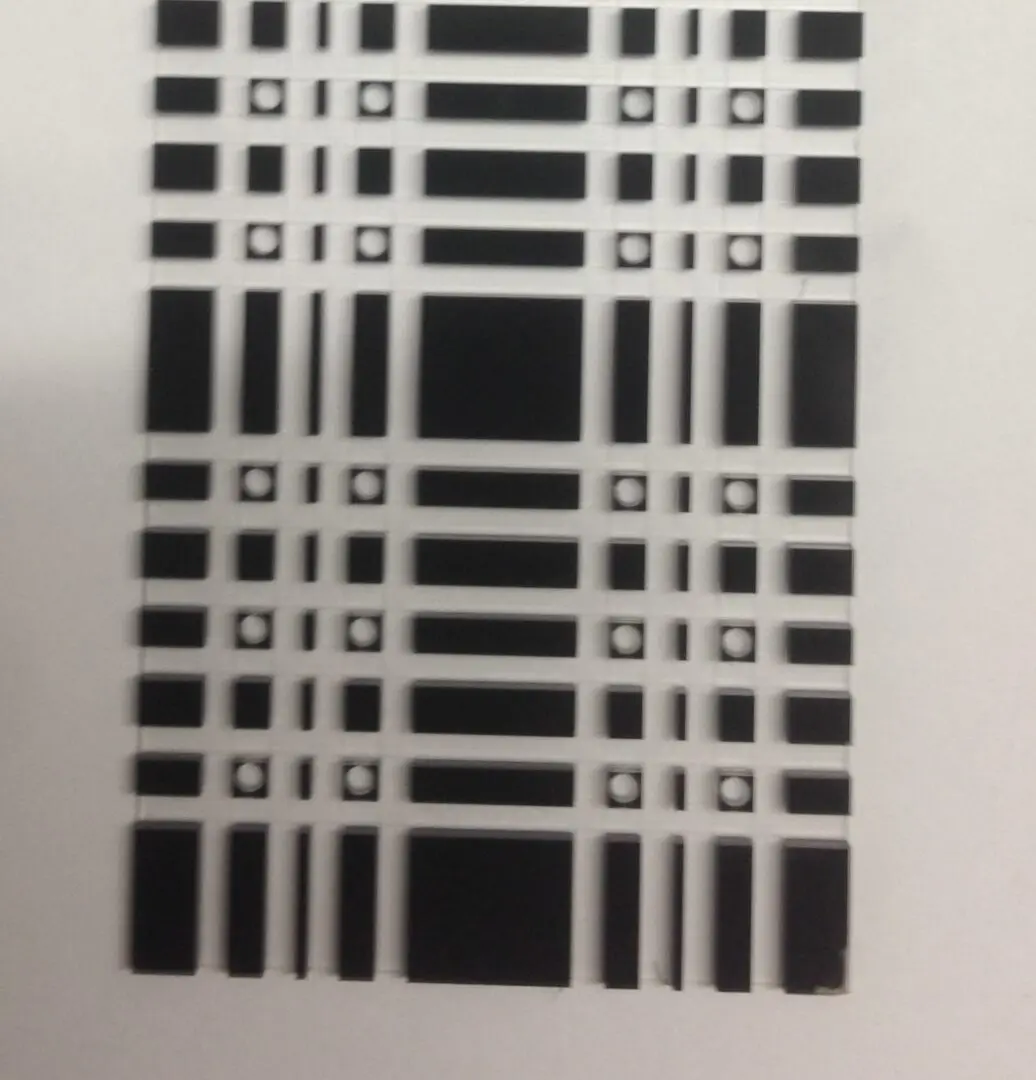

Dicing Services

Wafer Dicing

AIT currently operates 3 dicing saws that can handle up to 300mm substrates. The manual 125mm saw which is great for unusual dicing requirements where the cutting needs to be observed in real time.

There are 2 fully automated saws that can handle 200mm and 300mm respectively. The 300mm saw can also manage multiple 4” wafers in a single taping reducing time and cost of materials. Both machines work with cassettes to manage many substrates with automated alignment and cleaning modes.

Typical substrate materials include Silicon, Quartz (Fused Silica), Glass, Sapphire, Lithium Niobate, and Ceramics such as Aluminum Oxide (Al2O3) and Aluminum Nitride (AlN), and others. PCB’s and PZT materials can also be cut where extreme tolerances and pixelation are required.

Please have the following information available to expedite quotations:

Both X and Y

Our standard blades for silicon cut approximately 60 um, including chipping

Chipping depends on the coating surface, cutting parameters, and blade type.

Diameter and thickness

Lorem Ipsum is simply dummy text of the printing and typesetting industry.

For more information about the superior results our dicing services can achieve, we invite you to call us at (858) 566-2945 or submit an inquiry via our web form.