Micro Assembly Services

Assembly Services

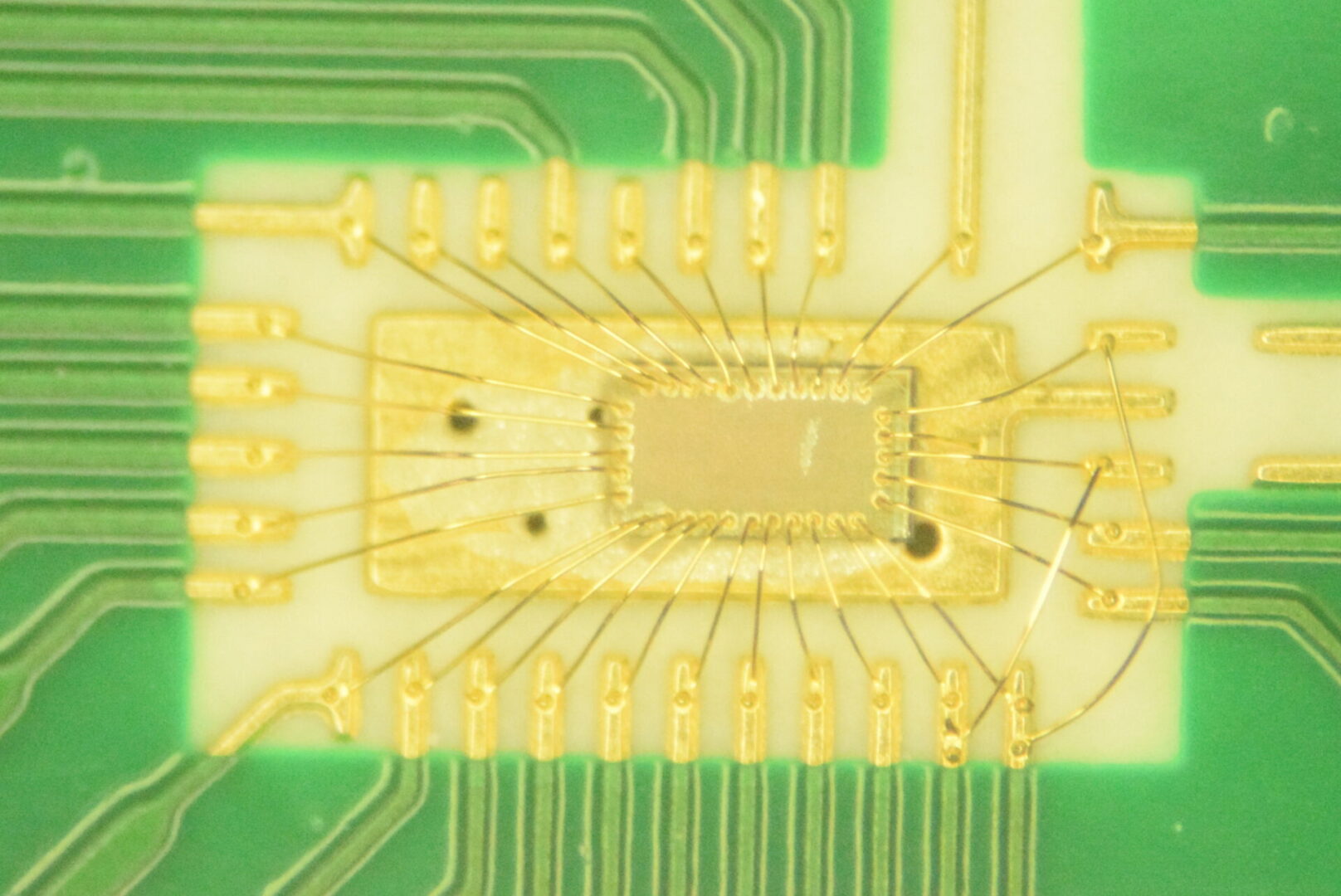

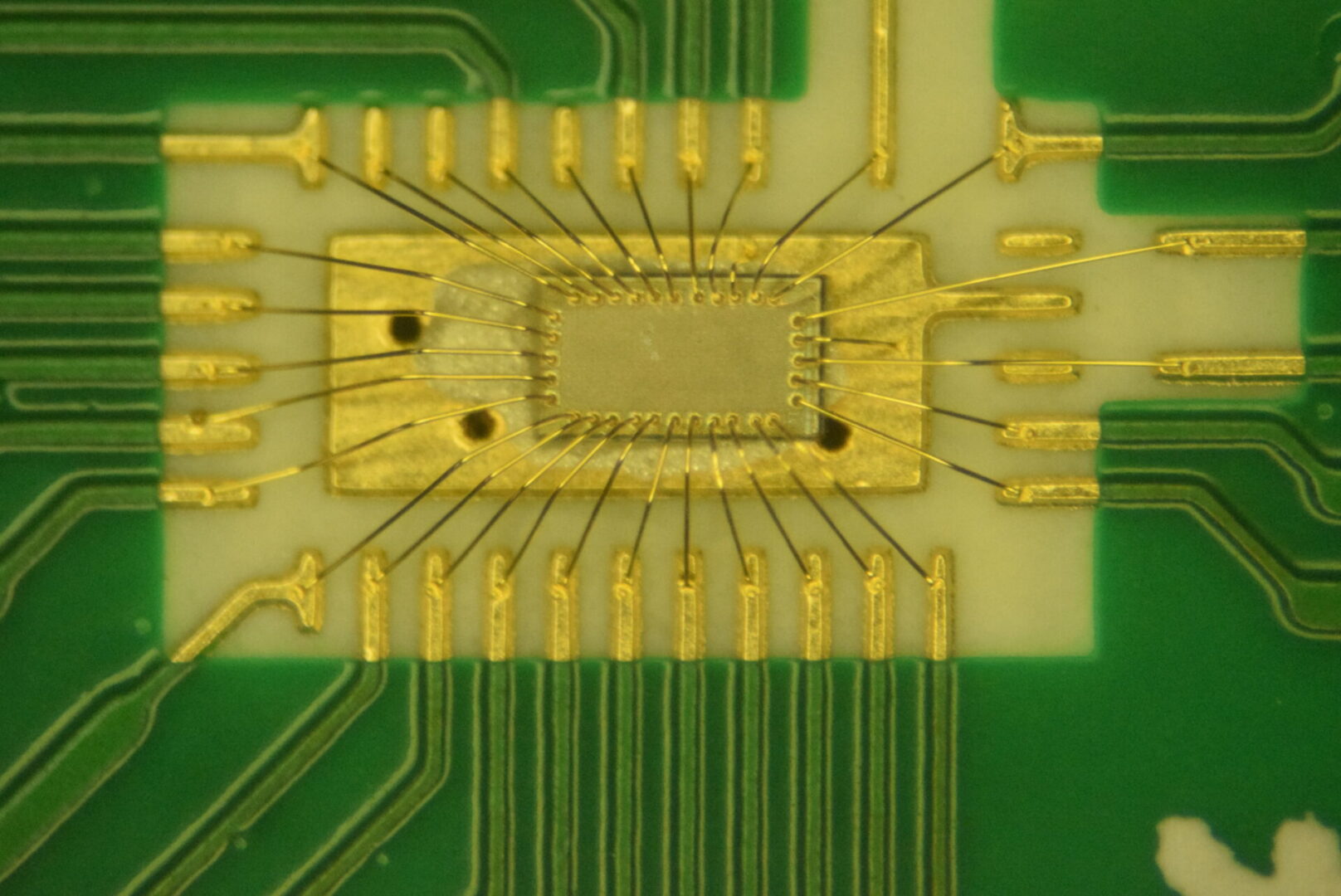

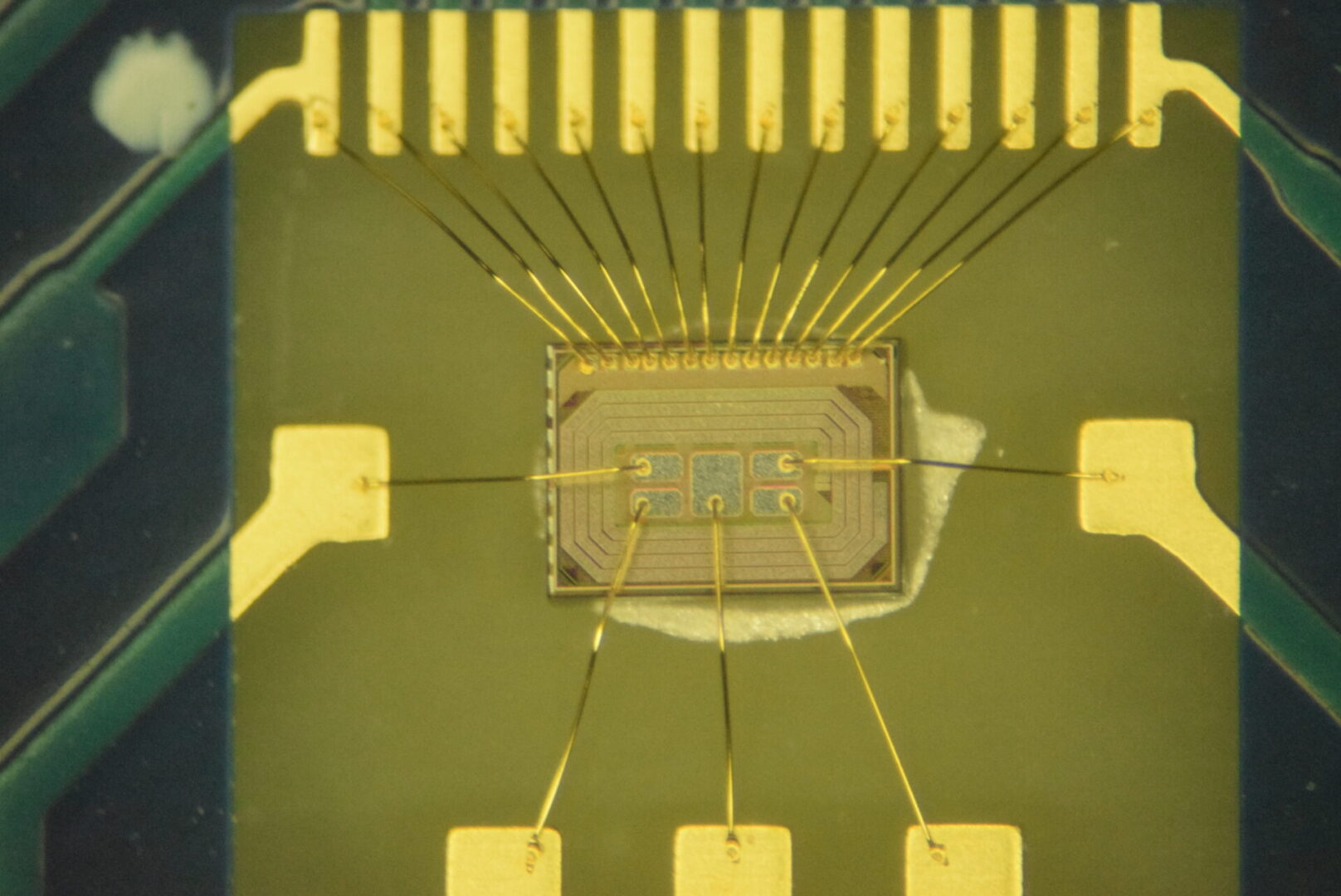

Assembly services typically involve die attach, wire bonding, and encapsulation.

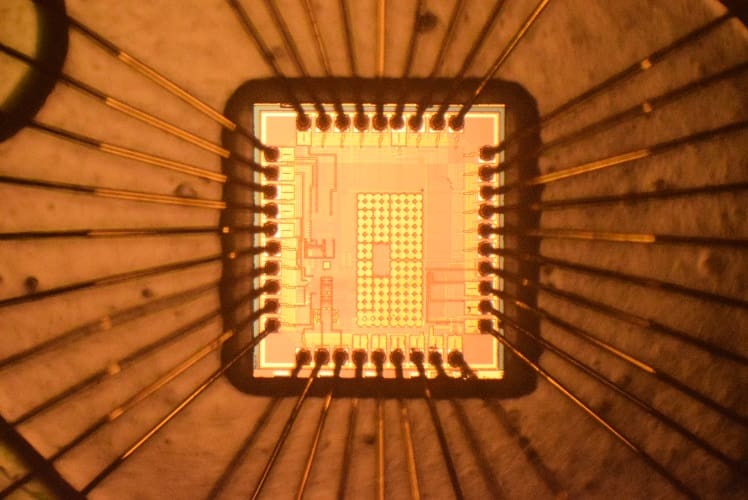

Die attach is usually performed with a Convertible Die bonder. We can dispense a variety of epoxies including solder paste where needed. The tip is capable of lifting dies down under 1mm. The robotic free floating arm has a 1:8 movement ratio and a finger tip rotation dial for accurate and precise handling and placement of dies.

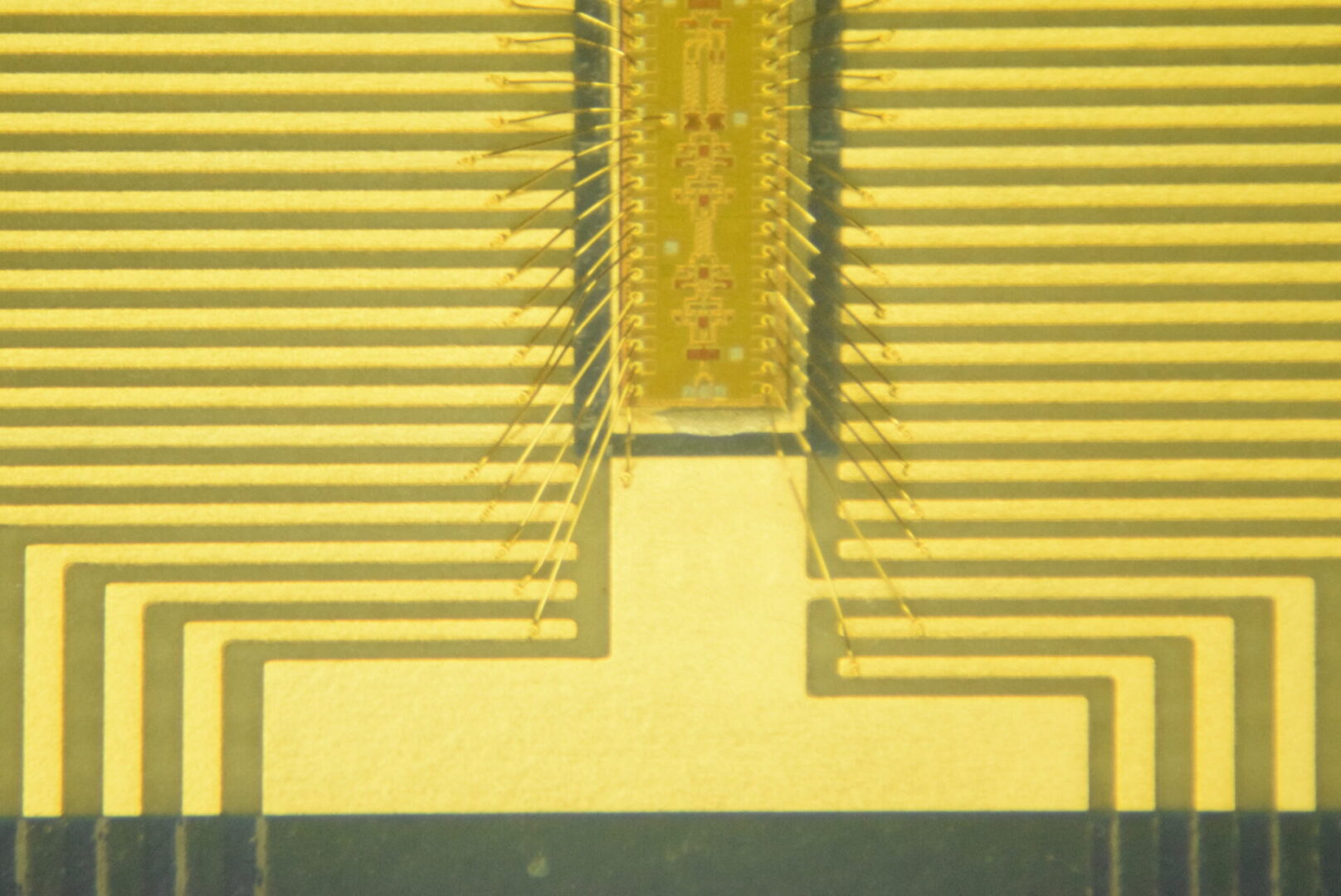

Our wire bonding service utilize multiple highly flexible machines to handle a variety of bonding applications. Bondable substrates typically include platinum, gold and aluminum. Other materials can be bonded given special treatments. We specialize in small to medium batch processing and are experienced with unusual wire bonding applications.

We have over 20 years of process knowledge and experience that allows for unusual configuration and temperature restrictions often sought out in the biotech and medical industries.

There are a variety of encapsulation configurations our customers require in which we have learned over the years to be able to be flexible to adjust our parameters to meet customer needs. We either glob top or dam and fill with high viscous epoxies to prevent run out and confine the epoxy where it is needed. Dispensing is either manually dispensed with our experienced assembly technicians or we have an automated D-585 Asymtek epoxy dispenser to dispense multiple epoxies and a large 21”x21” work area.

Please include the following information when asking for a quote:

Size of pads and minimum pitch (measured from the center of one pad to the center of the second pad)

If bonding to a PCB, please include the type of finish, the size of the board, and whether it is stuffed or bare.

For more information about the superior results our dicing services can achieve, we invite you to call us at (858) 566-2945 or submit an inquiry via our web form.